The purity of hydrogen can be up to 99.999%,

Electrolysis of pure water for hydrogen production, no corrosion, no pollution, high hydrogen purity;

Hydrogenproduction and storage with renewable energy

4256cm²

750 ×1180×760 (mm)

4035 kg

1.96V

4776 A

3.0 MPa

220 Nm3/h

>75%

2849cm²

560 ×1200×620 (mm)

2496kg

1.96V

3190A

3.0 Mpa

116 Nm3/h

>75%

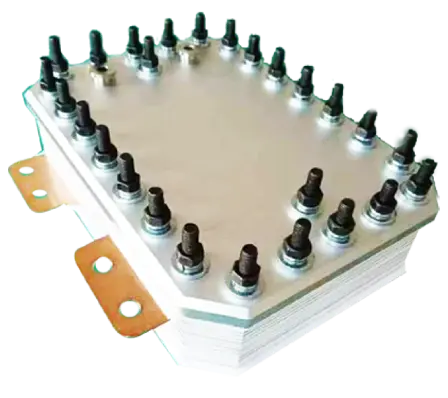

420cm²

480 ×330×310 (mm)

300 kg

1.96V

552A

3.0 MPa

11.6 Nm3/h

>75%